The pattern of holes on the module designated for a given slot. When implemented, only modules of the same type can be inserted in a given slot. An adequate number of key pins are shipped with the housings as part of hardware kit AS-8536-002. Figure 5-2 I/O Module Key Pin Insertion KEY PINS INSERT INTO MODULE HOUSING TO. The second number is the slot number of the 1756-DHRIO module of the DH+ network the PLC-5 processor is connected to. The third number is the channel of the 1756-DHRIO module that the PLC-5 processor is connected to. Use 2 for channel A and 3 for channel B. The final and fourth number is the DH+ node number.

Programmable Logic Controller (PLC) also known as Industrial Computer is the major component in the industrial automation sector. Due to its robust construction, exceptional functional features like PID controllers, sequential control, timers and counters, ease of programming, reliable controlling capabilities and ease of hardware usage – this PLC is more than a special-purpose digital computer in industries as well as in other control-system areas. Different types of PLCs from vast number of manufacturers are available in today’s market. Therefore, in the subsequent paragraphs, let us study about PLCs and their types.

What is a PLC System?

PLC is invented to replace traditional control panels whose operations depend on the electromagnetic logic relays that are based on timers in industrial control systems. PLCs are capable of monitoring the inputs continuously from sensors and producing the output decisions to operate the actuators based on the program. Every PLC system needs at least these three modules:

- CPU Module

- Power Supply Module

- One or more I/O Module

CPU Module

CPU module consists of a central processor and its memory. The Processor is responsible for doing all the necessary computations and data processing by accepting the inputs and producing appropriate outputs. Memory includes both ROM and RAM memories. The ROM memory contains the operating system, driver and application programs, whereas the RAM stores user-written programs and working data. These PLCs use retentive memory to save user programs and data when the power supply breaks or fails and to resume the execution of a user program ones the power is restored. Thus, these PLCs do not need any use of a keyboard or monitor for reprograming the processor each time. The retentive memory can be implemented with the use of long-life batteries, EEPROM modules and flash memory methods.

BUS or Rack

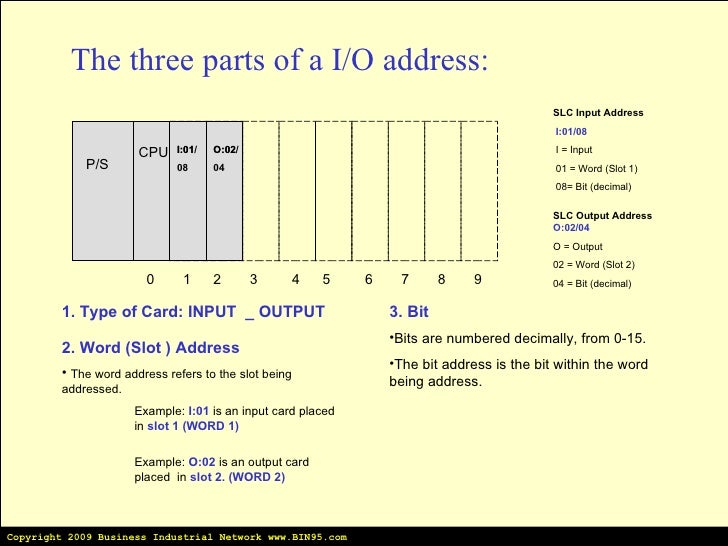

In some modular PLCs bus or rack is provided in the backplane of the circuit into which all the modules like CPU and other I/O modules are plugged to the corresponding slots. This bus enables the communication between CPU and I/O modules to send or receive the data. This communication is established by addressing the I/O modules according to the location from CPU module along the bus. Suppose, if the input module is located in the second slot, then the address must be I2:1.0 (second slot first channel only as an example). Some buses provide necessary power to I/O module circuitry, but they do not provide any power to sensors and actuators connected to I/O modules.

Power Supply Module

These modules supply the necessary power required for the whole system by converting the available AC power to DC power required for CPU and I/O modules. The output 5V DC drives the computer circuitry, and in some PLCs 24DC on the bus rack drives few sensors and actuators.

I/O Modules

Input and output modules of the PLC allow to connect the sensors and actuators to the system to sense or control the real-time variables such as temperature, pressure flow, etc. These I/O modules vary in type, range, and capabilities and some of these include the following:

Digital I/O module: These are used to connect the sensors and actuator that are of digital in nature, i.e., only for switch ON and OFF purpose. These modules are available on both AC and DC voltages and currents with variable number of digital inputs and outputs.

Analog I/O modules: These are used to connect the sensors and actuators that provide the analog electric signals. Inside these modules, analog to digital converter is used to convert the analog to processor understandable data, i.e., digital data. This module’s number of channel’s availability is also can be varied depending on the application,

Communication Interface Modules: These are intelligent I/O modules that exchange the information between a CPU and communication network. These are used for communicating with other PLCs and computers that are placed at a remote or far away distance.

Types of PLCs

Programmable Logic Controllers (PLCs) are integrated as either single or modular units.

An integrated or Compact PLC is built by several modules within a single case. Therefore, the I/O capabilities are decided by the manufacturer, but not by the user. Some of the integrated PLCs allow to connect additional I/Os to make them somewhat modular.

A modular PLC is built with several components that are plugged into a common rack or bus with extendable I/O capabilities. It contains power supply module, CPU and other I/O modules that are plugged together in the same rack, which are from same manufacturers or from other manufacturers. These modular PLCs come in different sizes with variable power supply, computing capabilities, I/O connectivity, etc.

Modular PLCs are further divided into small, medium and large PLCs based on the program memory size and the number of I/O features.

Small PLC is a mini-sized PLC that is designed as compact and robust unit mounted or placed beside the equipment to be controlled. This type of PLC is used for replacing hard-wired relay logics, counters, timers, etc. This PLC I/O module expandability is limited for one or two modules and it uses logic instruction list or relay ladder language as programming language.

Medium-sized PLC is mostly used PLC in industries which allows many plug-in modules that are mounted on backplane of the system. Some hundreds of input/ output points are provided by adding additional I/O cards – and, in addition to these – communication module facilities are provided by this PLC.

Large PLCs are used wherein complex process control functions are required. These PLCs’ capacities are quite higher than the medium PLCs in terms of memory, programming languages, I/O points, and communication modules, and so on. Mostly, these PLCs are used in supervisory control and data acquisition (SCADA) systems, larger plants, distributed control systems, etc.

Some of the manufacturers or types of PLCs are given below:

- Allen Bradley PLCs (AB)

- ABB PLCs (Asea Brown Boveri)

- Siemens PLCs

- Omron PLCs

- Mitsubishi PLCs

- Hitachi PLCs

- Delta PLCs

- General Electric (GE) PLCs

- Honeywell PLCs

- Modicon PLCs

- Schneider Electric PLCs

- Bosch PLCs

Applications of PLC

The below figure shows the operation of a PLC for a simple process control application wherein the conveyor belt operation, the number of boxes’ measurement and other control operations are performed by the PLC. Here, the position sensor and other sensor outputs are connected to the input module of the PLC, and from the output modules – a motor is controlled. When the sensors are activated, then the CPU of the PLC reads the inputs, and correspondingly processes them according to the program and produces the outputs to operate the motor so that the conveyor is controlled.

PLC and SCADA combination of control structure is mostly used in industrial automation sector and also in electrical utility systems like power transmission and distribution systems. Programmable sequential switching operation is another major application area of the PLC.

Therefore, the selection of PLCs for certain application needs several considerations over different types of PLCs. Thus we believe that the information here about the topic gives you a better understanding well supported by some appropriate and effective images. Do write to us if you have any technical doubts on this topic, and also on PLC based projects for students as well as for industries.

1.jpg)

Photo Credits:

- Programmable Logic Controller (PLC) by blogspot

- CPU Module of PLC by aotewell

- ABB PLC Power Supply by tlauk

- PLC I/O Modules by thomasnet

- Integrated or Compact PLCs by bse-tech

- A modular Types of PLC by delta

- Small, Medium and Large sized Types of PLCs by ecogate

- Manufacturers or Types of PLCs by amci

- Applications of PLC by ytimg

Before you can program any PLC system, you have to understand how the addressing is done in that particular PLC. I have included a actual screenshot from RSLogix 5000 below that shows examples of addressing in RSLogix 5000.

INSTRUCTION – RSLogix 5000’s Relay Ladder Logic command language is comprised of “instructions”. An XIC (it looks like a normally open contact –] [– ) is an instruction. A timer is an instruction. A few of the most common instructions are described below.

BIT – an address within the PLC. It can be an input, output or internal coil, among others.

RUNG – A section of the PLC ladder program that terminates in an output function of some type. Just like in an electrical ladder diagram, a rung has some type of output that is turned on or turned off by the preceding entities in the rung. The first rung in a ladder program is always 0.

HARDWIRED INPUT – a physical connection to the PLC from an input device (switch or sensor, etc.).

RSLogix 5000 defines the address of the input, based on the input cards that you configure.

We’ll see how this works later on, but here is an example of a hardwired input:

Local:4:I.Data.3

Here is what each part of the address means:

Local:4:I.Data.3

“Local” means that the module is connected to a controller across a backplane or with a parallel link, keeping the module within a few inches of the controller.

Local:4:I.Data.3

“4” means that the module is module 4 (located in the 5th slot in the rack).

Local:4:I.Data.3

“I” means the bit is an input

Local:4:I.Data.3

“Data” indicates the type of data (this is the default for I/O)

Local:4:I.Data.3

“3” indicates that the bit is 4th input on the card (the bits start with 0).

By the way, don’t get the capital “I’s” confused with ones.

So, in evaluating our example, we would describe the bit as “Module 4, bit 3”.

Here is where some confusion comes in. Because the Rockwell numbering system starts with 0, and the processor resides in Slot 0, our example bit is actually in slot 5. Our bit 3 is actually the 4th bit. We could also describe the bit as “Slot 5, position 4”.

You will have to learn to transpose these ways of describing a bit back and forth in your head. If you are troubleshooting a problem, and you want someone to look for a signal on our example bit, you might have to tell him to look at the 4th position on the 5th slot. That will lead him to the physical point on the PLC.

However, you need to keep in mind that the corresponding bit in your program will be labeled Local:4:I.Data.3.

It can be confusing, but you will get used to it.

HARDWIRED OUTPUT – a physical connection from the PLC to an output device (relay or pilot light, etc.)

Outputs are addressed the same way.

Local:5:O.Data.4

“Local” means that the module is connected to a controller across a backplane or with a parallel link, keeping the module within a few inches of the controller.

Local:5:O.Data.4

“5” means that the module is module 5 (located in the 6th slot in the rack).

Plc 5 Slot Numbering Machine

Local:5:O.Data.4

“O” means the bit is an output

Local:5:O.Data.4

“Data” indicates the type of data (this is the default for I/O)

Local:5:O.Data.4

“4” indicates that the bit is 5th output on the card (the bits start with 0).

INTERNAL COIL

This is a programmable bit used to simulate a relay within the PLC. The internal coil has no connection to the outside world. It does not connect to an output card. Internal coils are used to store information. The “contacts” of this “relay” can then be used multiple times in other parts of the program.

RSLogix 5000 has greatly simplified the process of describing an internal coil. We can simply give it a name, known as a tag.

For example, if you have an internal coil that is the result of, say, three hardwired safety gate limit switches, we could label the coil “SafetyGatesClosed”.

Note the lack of spaces in the tag name. RSLogix 5000 does not allow spaces, or other special characters, in the tag name.

Some people use underscores, so the tag might be “Safety_Gates_Closed”. Either way is fine; it just depends on what your company or your client prefers.

TIMER

A timer is a programmable instruction that lets you turn on or turn off bits after a preset time.

The two primary types of timers are TON for “timer on delay” and TOF for “timer off delay”.

Timers in RSLogix 5000 use tag names for identification.

COUNTER

A counter is a programmable instruction that lets you turn on or turn off bits after a preset count has been reached.

There are different types of counters available in the RSLogix, but the CTU (counter up) instruction covers everything we will talk about here.

Counters in RSLogix 5000 use tag names for identification.

–] [– Normally Open Contact

When used with a hardwired input, this instruction is off until there is a voltage applied to the input. The bit address then goes high, or on, and the instruction becomes “true.” It works the same way when it has the same address as an internal coil, except that the coil must be turned on by logic in the program.

Allen-Bradley calls these normally open contacts “XIC”, or “eXamine If Closed” instruction.

An XIC instruction can reference a hardwired input, a hardwired output, an internal coil or a timer done bit, among others.

–]/[– Normally Closed Contact

This is an inverted normally open contact.

When used with a hardwired input, this instruction is “true” until there is a voltage applied to the input. It then goes low, or off, and becomes “false.”

It also can be used with an internal coil, becoming true when the coil is off and becoming false when the coil is on.

Allen-Bradley calls these normally closed contacts “XIO”, or “eXamine If Open” instructions.

-( )- Output Coil

When used with a hardwired output, this function is off until the logic in the program allows it to turn on. It then becomes “true”, and will energize the device that is wired to the respective output.

If it is used as an internal coil, it will toggle the instructions associated with it. That is, it will close a normally open instruction and open a normally closed instruction.

Allen-Bradley calls these outputs “OTE”, or “OutpuT Energize”.

An OTE may be used with a hardwired output or an internal coil.

TRUE – A state that indicates an instruction is allowing logic to “flow” through it.

Plc 5 Slot Addressing

Also, if the logic in a rung turns on the output of the rung, then the rung is said to be true.

Plc 5 Slot Numbering Tool

FALSE – Without stating the obvious, this is the opposite of true.

Excerpted from PLC Programming with RSLogix 5000